A legend never dies. It exists to evolve.

The performance of cast sports wheels has reached maturity.

At some point, did we begin to subconsciously accept this conclusion?

Design optimization through computer analysis, increased rigidity and weight reduction via flow forming technology. With every technique established, the market is flooded with countless options. Among them, one model reigned supreme not just as a monument, but as the "benchmark" of an era: the WORK EMOTION CR Kiwami. Its perfected twin 5-spoke and concave design was the "definitive answer" of its time, inspiring a legion of followers.

But time does not stand still.

Vehicle dynamics have improved exponentially, and tires have achieved otherworldly levels of grip. Chassis now possess rigidity comparable to former race cars, feeding the driver immense amounts of information and demanding just as much in return.

In this torrent of rapid evolution, can the existing "benchmark" continue to meet the demands of the future?

Our answer is, No.

In addition, we make its next move to surpass the great monument it built with its own hands. This is no minor change, no simple measure to prolong a life cycle. It is a testament to the respect for past glory and the resolve to make it history.

This is not a generational change. It is a dimensional shift.

Its name is WORK EMOTION CR Shigoku.

To speak of the new "Shigoku," it is essential to look back at the achievements of its great predecessor, the WORK EMOTION CR Kiwami. Why was the "Kiwami" able to captivate so many people and continue its long run as a bestseller?

WORK EMOTION CR Kiwami / 19inch 10.5J +22mm / Ashed Titanium(AHG)

【A Design That Transcends Time】

The greatest appeal of the "Kiwami" lies in its timeless yet aggressive twin 5-spoke design.

Slender, sharp, and with a powerful concave profile dropping toward the center, the design eloquently spoke of the wheel's high dynamic performance even at a standstill.

This design became recognized worldwide as a symbol of JDM (Japanese Domestic Market) culture, dramatically enhancing the presence of countless vehicles, from sports cars to sedans and compacts.

Simple, yet possessing a powerful identity that is unforgettable once seen.

This is why the "Kiwami" has always shone as the "genuine article," even amidst the emergence of numerous imitations and similar products.

In 1998, we supplied the first forged magnesium 1-piece wheels in the domestic F3 series, becoming the origin of the WORK EMOTION line.

【A Performance Philosophy Rooted in the Streets】

The roots of WORK EMOTION lie in the racing scene.

However, its primary battlefield has always been the street. To sublimate technology forged on the grueling circuit into a joy that anyone can experience in daily driving—this has been the performance philosophy that WORK holds dear.

The "Kiwami" was the perfect embodiment of this philosophy. While being a cast wheel, it achieved a high-level balance of light weight and high rigidity by utilizing WORK's proprietary flow forming method, "WFT (WORK FLOWFORMING TECHNOLOGY)."

While delivering the fundamental performance required of a sports wheel, such as sharp handling and solid road-holding, it also offered the strength and durability essential for street use, all at an accessible price point. This exquisite balance is what earned it high praise from so many users.

The "Kiwami" was never just a part. It was a canvas that reflected the owner's individuality, a vital interface for deepening the dialogue with one's car. Because this great "benchmark" existed, the path to the next evolution was extremely clear, yet at the same time, incredibly challenging.

Why was it necessary to reinvent the perfected "Kiwami" now?

The answer lies within the brand philosophy of WORK EMOTION. That philosophy is to be a challenger who never rests on the standards they have set, but constantly strives to surpass them.

It is an unwavering will not to protect past glories, but to create the standards of the future and continue to lead the scene. This philosophy led us to a single conclusion: "If anyone can surpass the great 'Kiwami,' it is none other than ourselves."

And the development concept put forth to embody this challenger's spirit was distilled into one, simple phrase:

"The Legitimate Evolution of Kiwami."

The product development plan simply states the concept as "the legitimate evolution of KWM." Within these few words lies the deep resolve and confidence of the development team.

This is no radical design change, no superficial model update just to follow a trend. It is to fully inherit the essential appeal of the "Kiwami"—its DNA as the face of WORK EMOTION—and update every single element to match modern technology, modern vehicles, and modern demands.

That is the mission entrusted to the "Shigoku."

In development, a key focus was to "express the modern form of EMOTION."

In recent years, a wave of high-performance sports coupes like the GR86/90 Supra, the new Civic, and the Fairlady Z have been launched.

These vehicles have evolved dramatically not only in engine power but also in chassis performance and aerodynamics. Consequently, wheels are required to have higher rigidity, lower weight, and a design that effectively cools the braking system more than ever before.

The "Shigoku" is aimed squarely at this new generation of sports cars.

It was designed to be a partner that unleashes 100% of their potential and pushes them even further, with a thorough enhancement of performance.

Development energy was concentrated on improving its appeal as a pure "sports wheel," with a focus on weight reduction and the optimization of every component.

Behind the term "legitimate evolution," let's unravel the specifics of the transformation by examining the details of "Shigoku's" design and performance.

At first glance, its silhouette undeniably carries the bloodline of the "Kiwami." But the closer you look, the more you will be astonished by the new design cues and technologies embedded within.

A 15mm radius ball-end mill glides across a surface meticulously calculated from the initial casting stage. This process gives birth to the artistic side machining, guided by stress analysis.

A 15mm radius ball-end mill glides across a surface meticulously calculated from the initial casting stage. This process gives birth to the artistic side machining, guided by stress analysis.

【A Fusion of Design and Technology: The Inevitable Beauty Born from Function】

The greatest evolution in the "Shigoku's" design is the "side machining" applied to the spokes.

This process involves boldly carving into the sides of the spokes, not only contributing to weight reduction by removing unnecessary material but also creating a dramatic effect on the design.

The way light hits the surface creates shadows, making the spokes appear more slender, sharper, and three-dimensional.

Its expression is breathtaking, not only at a standstill but especially when in motion. The dynamism woven by light and shadow gives the wheel a new sense of life that the "Kiwami" never had.

Furthermore, its form carves a deeper, sharper, and more aggressive concave angle that seems to pull everything toward its center.

This is a form born from necessity, not just for visual impact, but also from the functional requirement of providing ample clearance for massive modern brake calipers.

So, how was this design, a crystal of functional beauty, created? The answer lies in the fusion of two of WORK's core technologies.

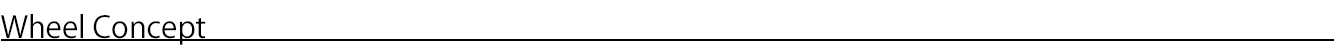

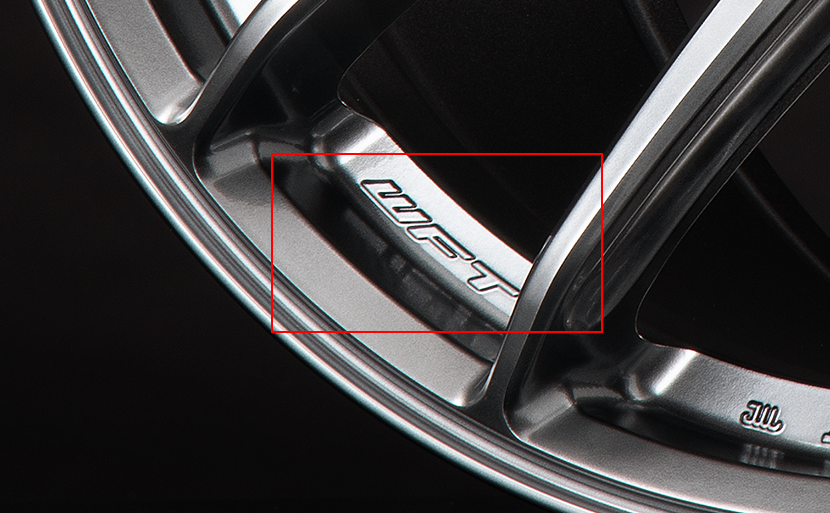

An engraving permitted only on wheels manufactured with the WFT (WORK FLOWFORMING TECHNOLOGY) method.

First, the foundation is the "WFT" rim-spinning process. This technology forges the rim section while forming it, ensuring strength comparable to a forged wheel. Then, on this solid foundation, only the non-essential parts of the spokes, as determined by stress analysis, are precisely machined away.

This combination of a robust skeleton (WFT) and extreme machining is the very core of the "SHIGOKU's" design philosophy, making it possible to maximize physical performance without any compromise on design.

The WORK EMOTION CR SHIGOKU is reliably Made in Japan. It is manufactured in a domestic factory that meets WORK's notoriously strict quality standards.

Left: Armed Titan Bronze (A passionate, reddish bronze that harbors the light of dawn)

Center: Glow Gunmetal (A deep, lustrous gunmetal that intelligently reveals the machine's frame in the dark of night)

Right: Ice White (A glacial color that shines under light and beautifully carves even the shadows)

An engraving permitted only on wheels manufactured with the WFT (WORK FLOWFORMING TECHNOLOGY) method.

First, the foundation is the "WFT" rim-spinning process. This technology forges the rim section while forming it, ensuring strength comparable to a forged wheel. Then, on this solid foundation, only the non-essential parts of the spokes, as determined by stress analysis, are precisely machined away.

This combination of a robust skeleton (WFT) and extreme machining is the very core of the "Shigoku's" design philosophy, making it possible to maximize physical performance without any compromise on design.

Center: Glow Gunmetal (A deep, lustrous gunmetal that intelligently reveals the machine's frame in the dark of night)

Right: Ice White (A glacial color that shines under light and beautifully carves even the shadows)

The logo embodies a philosophy clearly distinct from that of the "Kiwami." While the "Kiwami" proudly displayed its Kanji logo on the surface as if to flaunt its performance, the "Shigoku" conceals its name on the reverse side.

This is to express a more internal and profound relationship—the realm where driver and car become one, known as "Jinba Ittai" (the unity of horse and rider).

The wheel is no longer just a functional part, but a part of the nervous system that transmits the driver's will to the road. This idea is symbolized by the blue gradation of the "Shigoku" logo, which quietly speaks of a passion that surpasses even the "Kiwami."

If the evolution of design is "deepening," then the evolution of performance deserves to be called "transcendence."

The development team cited the most difficult challenge of "optimizing each component (rigidity and overall dynamic balance) while balancing weight reduction without compromising the Kiwami design balance."

The "Shigoku" offers a surprising solution to this challenge.

Proof of the "Shigoku's" special status is the "WAE" engraving on the spoke. "WORK ADVANCED EDITION"—these three letters are a mark of honor bestowed only upon products that have broken through design limitations using the latest advanced computer analysis technology.

Left: WORK EMOTION CR Shigoku

The width of the spoke base, indicated by the red line, is actually narrower and sharper than the KIWAMI's. At first glance, this might seem disadvantageous for rigidity. However, this is the very core of Shigoku's technical evolution. To solve the paradoxical challenge of increasing the strength test values (from 700KG to 720KG) while achieving significant weight reduction through side machining, the shape was optimized through stress analysis to reinforce only the areas where strength is truly needed. This sharp shape is the inevitable form born from function, stripping away all excess and meticulously calculating the flow of stress.

Right: WORK EMOTION CR Kiwami

On the other hand, the same area on the Kiwami is thicker and connects to the hub with a smooth curve. This is a conventional and highly reliable design philosophy that ensures rigidity with ample material margin.

The evolution is clearly demonstrated by concrete numbers. Below is a weight comparison between the Kiwami (KWM) and the Shigoku (SGK).

Size KWM Weight SGK Weight Difference

19105+32 / +22 11.20kg 10.93kg ▲0.27kg

1995+38 10.74kg 10.05kg ▲0.69kg

18105+22 10.80kg 10.37kg ▲0.43kg

1895+38 10.20kg 9.63kg ▲0.57kg

1885+38 9.80kg 9.20kg ▲0.60kg

1875+53 9.03kg 8.75kg ▲0.28kg

Note: The weights shown are target design values. Individual products may vary due to manufacturing tolerances.

Weight has been reduced across all sizes, with a remarkable reduction of 0.69kg per wheel for the 1995+38 size. It is said that reducing unsprung weight has an effect on athletic performance several times greater than reducing the weight of the suspension or the entire vehicle body. Sharper handling, improved acceleration/deceleration response, better ride comfort, and increased fuel efficiency—the greatest benefit a user gains by choosing this product is the dramatic improvement in the quality of the drive, brought about by this "light weight and high rigidity."

What is even more noteworthy is that it hasn't just become lighter.

The test data reveals a stunning fact: Test Load Value: KWM: 700KG / SGK: 720KG.

This means that in strength testing, the "Shigoku" clears a stricter standard (+20kg) than the "Kiwami."

In other words, the "Shigoku" is lighter and stronger than the "Kiwami." This is truly a technical breakthrough and the most eloquent evidence supporting the term "legitimate evolution."

It's not just about performance and design; it is also fully compatible with features essential for modern vehicles. It supports Tire Pressure Monitoring Systems (TPMS) and M14 size bolts/nuts, allowing for safe installation on a wide range of cars.

A variety of center caps are available as options. Please see the [PARTS] section for details.

So, what kind of impact will this wheel, the "Shigoku," have on users and the industry, and what kind of future will it create?

Absolute Superiority: The Story of the Authentic Lineage

The greatest advantage of the "Shigoku" is the story behind it. The twin 5-spoke design, passed down through generations, is a unique presence in the market, and its lineage is proof of its authenticity. The evolutionary context from the "Kiwami," the struggles of development, and the technological leaps—a story that imitations can never tell. This entire narrative makes the value of the "Shigoku" absolute.

Users don't just acquire a wheel; they gain the pleasure of owning the history and innovation of WORK EMOTION itself.

The arrival of "Shigoku" marks the setting of a new standard in the sports wheel market.

As the words "a new generation of WORK EMOTION" suggest, this is the first step toward the next stage for the entire brand.

By rewriting the "standards" that Kiwami has built over the years, we will lead the technical level of the entire industry and provide users with an even more exciting driving experience than ever before.

WORK EMOTION CR Shigoku.

If one were to describe this wheel in a single phrase, it would be "the apex of legitimate evolution."

Paying the utmost respect to its great predecessor, the "Kiwami," it inherits its soul and design while thoroughly refining its performance with the best of modern technology. Lighter, stronger, and more beautiful.

It is truly a new-generation benchmark that fuses all the elements required of a sports wheel at an unprecedented high level.

The throne of the king is not for protecting, but is granted only to those who constantly challenge and continue to evolve. The arrival of the "Shigoku" is a powerful declaration that WORK EMOTION is the true king.

Now, let's raise the curtain on a new legend. The protagonist on this stage is none other than you, and the "Shigoku."